How it came about

In the early 90s, Dr. Masaki Morikawa, a metallurgist and plant manager at Mitsubishi Materials Corporation in Japan, was inspired to create a type of clay obtained from the precious scraps left over from the manufacturing process. His experiments led to what we know today as Precious Metal Clay (PMC®).

At the same time, scientists at Aida Chemical Industries have developed a similar material, now known as Art Clay Silver (ACS®). Art Clay Silver is the brand that focused more on the European market, where it appeared around 1995, and in Romania in 2013.

What is a metal clay, the metal in the form of clay?

Metal Clay (metal clay) is the result of modern alchemy. It's a really versatile material, while also being a material ecological, because it is obtained by recycling precious metals and not only.

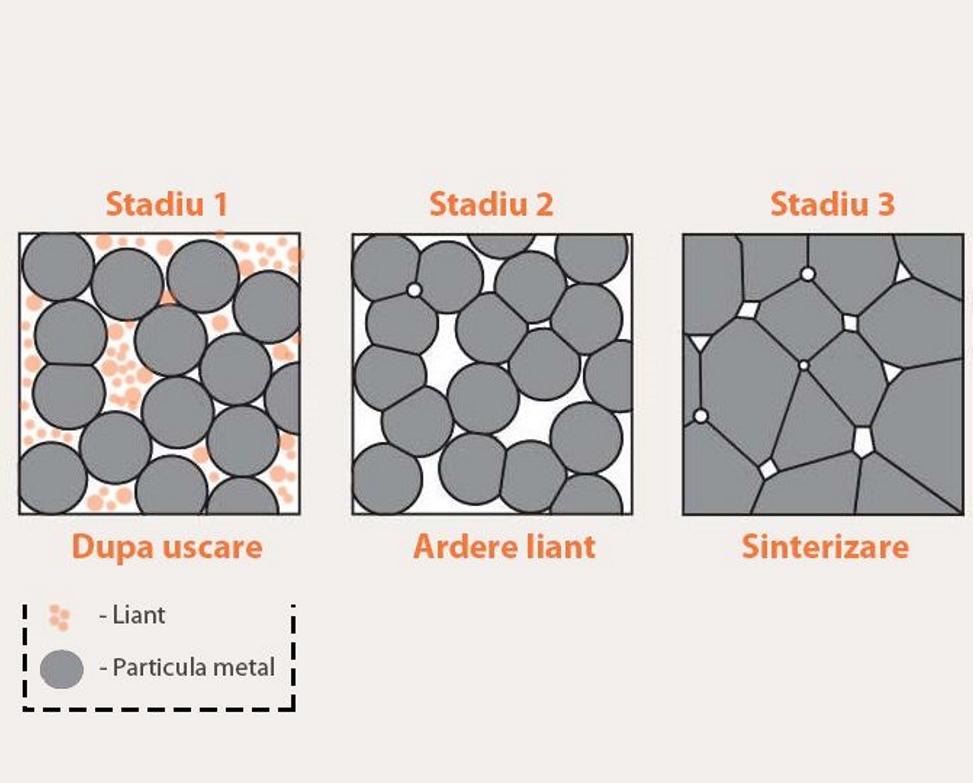

Metal clay it contains metal powders, water and a small amount of substance, which acts as a binder. In this way, a material with the consistency of clay, easy to model, is obtained. It can be modeled, sculpted, engraved, applied by painting, as a decoration or as a mold, just like ceramic or modeling clay. The basic processing steps are: shaping, drying and firing (at over 650 ºC). During combustion, the sintering process occurs.

What is sintering

Sintering is a process by which fine particles of material are "glued" together to form a solid mass. The process takes place by heating, without reaching the melting point of the material. The term sintering is also used in ceramics, plastics or other materials.

Sintering involves shrinking the part due to the evaporation of water contained in the metal in the form of clay and the burning of the binder. The metal particles come together and stick to each other and thus the size of the piece is reduced. It should be noted that the clay metal shrinks / contracts in volume, ie in all dimensions: height, depth, length, circumference and thickness.

New technology? Not quite...

Indeed, it is a new technique used to create jewelry, but metal powder has been used for thousands of years. The Egyptians were among the first to convert metals into powder or granules to obtain objects that were too large to be burned in their melting furnaces. Metal powder has been used for commercial purposes for centuries. For example, in dentistry it is used in the creation of dental crowns. But in the making of jewelry began to be used only in the '90s.

Types of metal clay

Metal clay it comes in various shapes and compositions to give you endless creative possibilities. Currently it can be found metal clay from: gold, silver (999, 950, 960, 925), copper (various shades), brass (various shades), bronze (various shades) or steel. Moldable metal can be purchased in clay, paste, syringe, paper, or powder form.

Now, thirty years after its invention, there are over 21 manufacturers worldwide making over 120 different types of metal clay from different alloys and having different working properties.

conclusions

After the stages of modeling, drying and firing, once reached the solid / sintered metal stage, the resulting object can be textured by hammering or milled. It can also be sawed, perforated or applied by soldering other metal or metal clay components and it can be molten for reuse.

Metal clay it is probably the only material from metal powders, moldable, which can be processed and formed artistically both in the moldable (raw) and in the solid state. Metal Clay it gives you infinite possibilities to express your creativity!